R A Power Solutions is India’s leading specialist for in-situ crankshaft grinding and onsite crankshaft grinding, precision in-place grinding, polishing, and rebuilds for marine, power plant, and industrial engines across India. We offer 24/7 rapid response, adhere to OEM tolerances, and follow class-approved procedures.

When a crankshaft fails or journals wear beyond tolerance, downtime costs can rise rapidly. RA Power Solutions delivers fast, reliable onsite crankshaft grinding and insitu crankshaft grinding services across India—restoring main journals and crankpins to OEM specifications without removing heavy components or taking engines to remote workshops. Our experienced teams, bespoke portable grinding machines, and class-approved procedures minimize downtime and get vessels, power plants, and industrial units back to work quickly.

Why Choose Insitu/Onsite Crankshaft Grinding?

Unlike workshop-only repairs, insitu crankshaft grinding (grinding done in place) removes the logistical delays, transport risks, and high costs associated with dismantling and shipping large crankshafts.

R A Power Solutions combines decades of field experience with vibration-free, portable grinding machines to deliver:

- Precision grinding and polishing to OEM tolerances

- Minimal downtime— repairs are typically performed on site, often while the asset is in port or at the plant.

- Full inspection, MPI, and metallurgical options (hardness tests, crack detection, rebabbitting) where required.

Core services offered by R A Power Solutions in India

Below is a consolidated, searchable list of the work RA Power performs across India —

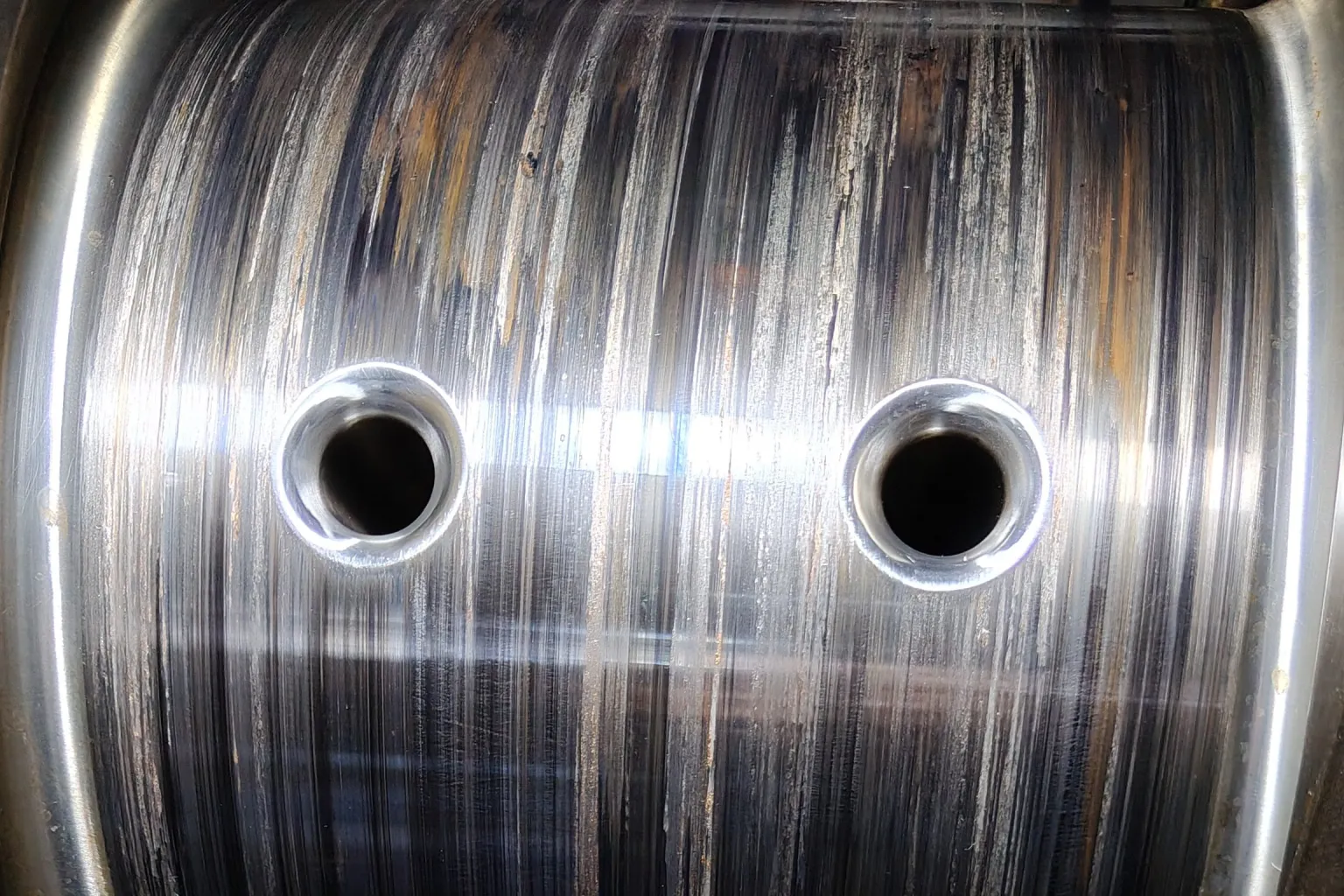

(1) Insitu / Onsite Crankshaft Grinding & Polishing

- Grinding and polishing of crankpins and main journals (diameters typically from ~35 mm up to 700 mm).

- Vibration-free portable grinding machines developed and manufactured in-house for safe in-place machining.

(2) Emergency onboard repairs (vessel & shipyard support)

Rapid deployment teams are available for vessels, which can perform repairs while sailing or at anchorage, thereby avoiding extended port stays.

(3) Crankshaft rebuilding:

Rebuilding smaller crankshaft parts by adding material with thermal spray or metal buildup, then carefully machining them to match original sizes and hardness.

(4) Connecting rod, engine block & cylinder head repairs

We provide services such as con-rod alignment, engine block metal-locking/metal-stitching for crack repairs, and cylinder head overhaul.

(5) Rebabbitting & bearing services

The services include bearing rebabbitting, white-metal casting/reconditioning, and the provision of reconditioned spare parts.

(6) Turbine, rotor & compressor shaft grinding & polishing

Insitu shaft grinding and balancing for turbine rotors, compressor shafts, and other rotating equipment.

(7) MPI, inspection & testing

Crack detection, hardness testing, alignment verification, and detailed inspection reports—class-approved procedures and documentation.

(8) Sale, training & support for portable crankshaft grinding machines

We supply portable onsite grinders, provide operator training, and offer after-sales technical support across India; these machines have proven to be cost-effective, with many units sold worldwide.

Representative works & capability highlights in India

R A Power Solutions has an established base in Gurgaon and operates throughout India’s shipyards, ports, and power plants. Key capability highlights and examples of the types of jobs executed in India:

- Precision onsite crankshaft grinding of marine auxiliary and main engines (examples include repairs on popular engine platforms such as Daihatsu and Wartsila).

- Indian shipyards and coastal repair facilities provide emergency crankpin and main journal restoration services.

- In-place repairs for land-based power plants and industrial engines—crankshaft grinding, con-rod overhauls, and engine block metal-locking.

- Rebuilt and reconditioned crankshafts returned to service after thermal spray deposition and re-machining; thorough inspection and class approval where required.

R A Power Solutions reports decades of experience and thousands of crankshaft repairs worldwide, reinforcing their capacity for large, complex jobs.

Benefits — business value of choosing RA Power Solutions in India

- Reduced downtime and logistic costs versus workshop removal.

- Class-approved, OEM-aligned repairs that protect asset life and safety.

- Local presence in India with international know-how and 24/7 availability for emergencies.

For urgent Insitu crankshaft grinding and Onsite Crankshaft grinding across India or worldwide, contact R A Power Solutions today. We offer rapid mobilization, class-approved procedures, and proven in-place grinding machines.

Phone: +91 9582647131 | Email: info@rapowersolutions.com.