RA Power Solutions offers advanced insitu crankshaft grinding and polishing machines designed and developed using innovative production techniques. With over 45 years of experience, we continuously optimize our machines to meet the highest international standards through rigorous design and performance testing.

Over the decades, we have catered to a wide range of industries by delivering custom-designed, portable onsite crankshaft grinding machines. These machines provide an economical solution when only one or two crankpins are damaged, eliminating the need to dismantle or ship the entire crankshaft to a distant workshop.

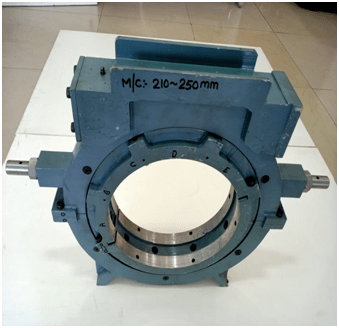

We engineer our compact and lightweight machines specifically for insitu grinding and polishing of crankpins ranging from 50 mm to 600 mm in diameter, eliminating the need to remove the crankshaft from the engine block. Their innovative design allows technicians to insert them through the engine’s inspection window and set them up quickly, even in confined spaces.

Key Features:

- Onsite Operation: No need to dismantle the crankshaft—repairs can be done directly inside the engine block.

- Compact & Portable: Easy to transport and suitable for onsite repairs anywhere in the world.

- Dual Functionality: Both grinding and polishing can be carried out using the same machine.

- User-Friendly: Simple setup with easy alignment for precision repair.

- Accurate Results: Maintains precision up to 10 to 25 microns and achieves RA surface finish as per OEM standards.

- Multiple Drive Options: Operates using pneumatic, electric, or hydraulic power.

- Comprehensive Support: Training, operation manuals, spare parts, and after-sales services are readily available.

- Technical Specifications:

Crankpin Diameter Range: 50 mm to 600 mm - Accuracy: Up to 10 to 25 microns

- Surface Finish: Achieves OEM-specified RA values

- Design: Compact, lightweight, and easy to operate

Applications:

Our insitu crankshaft grinding machine is ideal for a wide variety of industries and equipment, including:

- Marine & Diesel Engine Crankshafts

- Reciprocating Compressors & Pumps

- Industrial Process Shafts

- Turbines, Rollers, and Fracture Pump Crankshafts

- Any shaft requiring high-precision machining and superior surface finish

RA Power Solutions ensures minimal equipment downtime, cost-effective repair solutions, and world-class service support. Whether at sea or on land, our onsite crankshaft grinding machines keep your engines running smoothly without the delays and costs of workshop-based repairs.

For more information regarding crankshaft grinding services or onsite crankshaft repair, please contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com or call us at +91 9582647131 or +91 9810012383.

FAQs

It is a portable, high-precision machine designed to grind and repair crankshaft journals onsite without removing the crankshaft from the engine.

It reduces downtime, eliminates the need for shaft removal or transportation, lowers repair costs, and restores the crankshaft’s original surface finish and alignment.

Our machines can handle crankshafts with diameters ranging from 30 mm to 700 mm, making them suitable for marine engines, power plants, and industrial machinery.

Yes, it is ideal for marine diesel engines, auxiliary engines, compressors, and generator sets across various industries.

We use state-of-the-art equipment, calibrated instruments, and follow strict quality control protocols to achieve accuracy within OEM tolerances.

Telephone No.09582647131