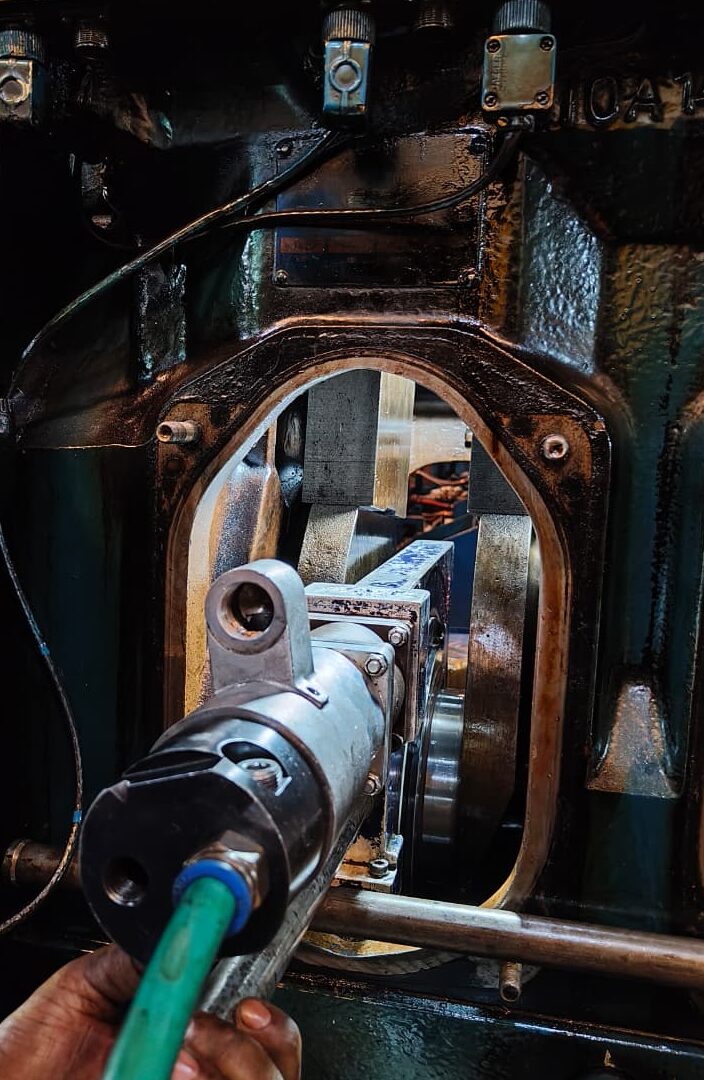

Insitu Crankshaft Repair

In situ crankshaft repair is the optimal solution when delay is not an option. Our team brings the expertise, tools, and technology directly to your site, eliminating the need to disassemble the engine and transport the crankshaft to a workshop, a procedure that can take weeks. This method not only eliminates the hazards associated with handling heavy components during transportation but also saves a significant amount of time and reduces costs.

R A Power Solutions‘ highly trained engineers use state-of-the-art portable machining and grinding equipment to restore crankshaft surfaces to exacting OEM tolerances. Each repair is executed in accordance with rigorous quality control protocols, guaranteeing that your crankshaft will regain its full operational efficiency and extend its service life accordingly. Whether you are managing heavy industrial equipment in continuous operation, operating a power plant in a challenging location, or operating a marine vessel in a remote port, we can be onsite anywhere in the world.

The procedure commences with a comprehensive examination that employs cutting-edge measuring instruments to detect any signs of wear, scoring, or damage. Our team determines the most effective repair method to accomplish the desired finish, which may include precision grinding or polishing, based on the assessment. We consistently prioritize the provision of the most rapid turnaround time possible while maintaining the highest standards of accuracy and durability.

We have assisted shipowners, power plant operators, and industrial clients in avoiding costly replacements and protracted delays, based on our more than 45 years of proven experience in insitu crankshaft repair. Our mobile teams are prepared to respond to emergency malfunctions or scheduled overhauls at any time. By selecting us, you are selecting technical excellence, reliability, and the assurance that your engine will be operational sooner than you anticipated.